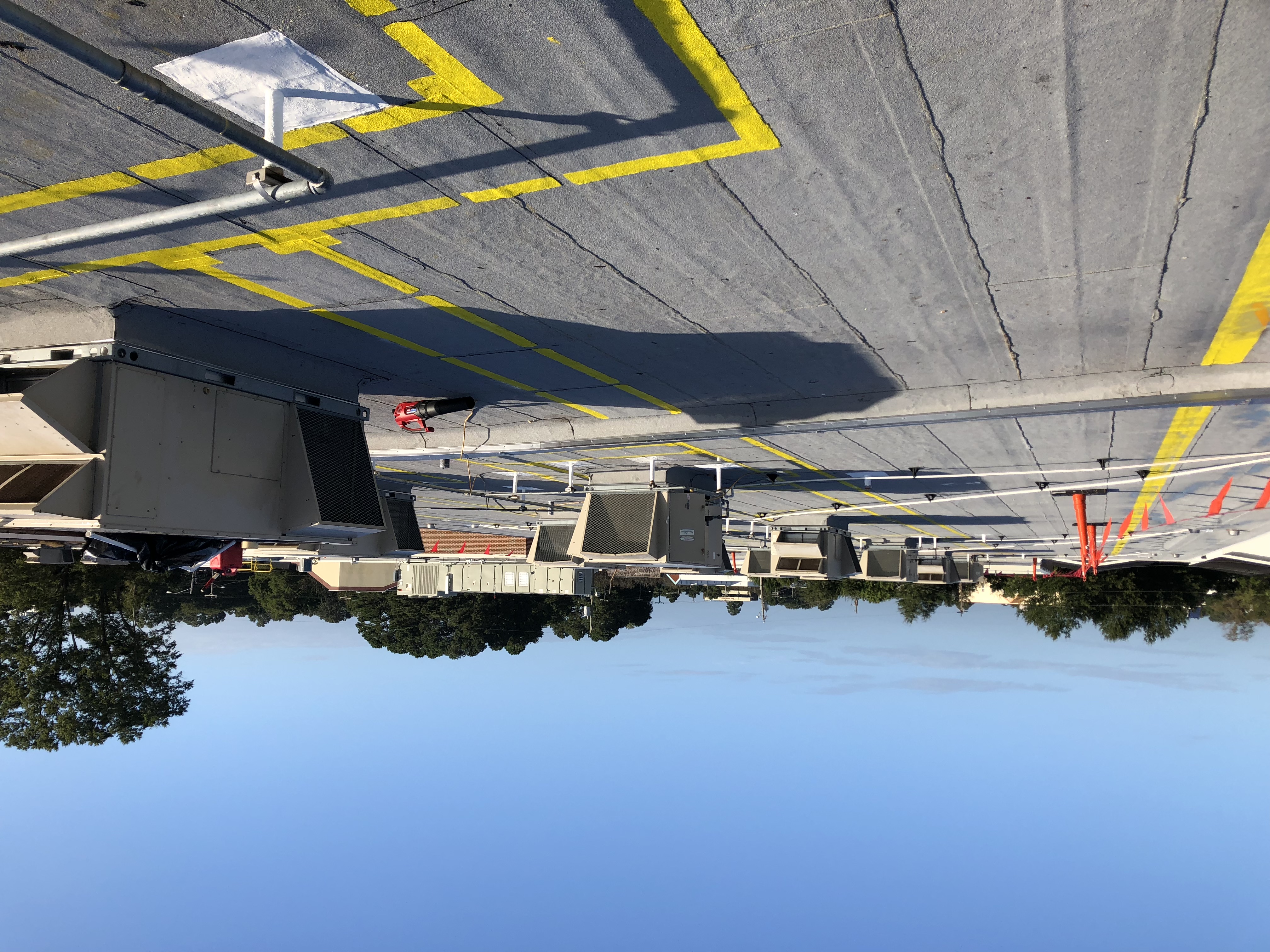

Phase I of this fast-track roof replacement was successfully completed through careful sequencing, multi-trade coordination, and multiple daily mobilizations. Roof demolition was tightly coordinated with MEP demolition activities to maintain progress and site safety. Daily operations utilized a 6K LULL forklift, all-terrain scissor lifts, trash hoppers, and multiple dumpsters to support continuous workflow.

The project included removal and salvage of the building’s natural gas line up to a newly installed isolation valve. ACCU branch lines were relocated, and the main line was reinstalled in phases using new galvanized, adjustable Thybar pipe supports. Rusted decking areas were treated with a rust inhibitor, and the perimeter of the existing roof deck was mechanically fastened from eave to corner to meet ASCE 7 uplift requirements. Roof decking was selectively replaced and secured to structural supports, and abandoned rooftop exhaust fans were removed and infilled with new metal decking.

Concrete coring was performed to accommodate additional roof drains, new overflow drains, and downspout nozzle penetrations. Masonry work included removal and infill of approximately 30 architectural louvers and brick infill at abandoned rain leader locations. Several areas with failing brick headers were repaired and rebricked from sill to eave. EIFS repairs were completed where rain leader piping had been cut and capped.

Metal fabrication scope included installation of three new galvanized roof ladders and RTE equipment curbs. A pre-engineered edge metal system was installed, along with field-fabricated standing seam expansion joint covers featuring welded end caps, miters, corners, stainless steel receivers, terminations, and additional custom metal flashing components. Stormwater management improvements included approximately 500 linear feet of powder-coated gutters and downspouts terminating onto concrete splash blocks.

Skilled carpentry supported edge metal installation, wood cant strips, blocking details, expansion joints, and roof dividers. Interior plumbing improvements included roof drain relocations, new cast iron drain piping, clevis hangers, insulation, additional horizontal rain drainage, and extension of vent-through-roof penetrations. Roof drain bowls were fully replaced, and new overflow drains with downspout nozzles were installed, requiring daily coordination with roofing demolition activities.

Smart Box pipe chase curbs were installed at locations housing 1.5-ton ductless split systems. Exhaust fan whips and curbs were extended where roof system clearance requirements were not met. ACCUs received new PVC condensate piping on pipe supports to provide secondary drainage, and new boiler flue flashing was installed.

The roof replacement addressed a system originally installed in 1996 across the 1956 and 1993 portions of the building. The existing multi-ply built-up roof with gravel flood coat was replaced with a new two-ply cold-process SBS modified roofing system installed over new polyisocyanurate insulation, delivering improved performance, durability, and long-term protection.